September 21, 2016

UOW a model of innovation

The Hon Greg Hunt MP, Minister for Industry, Innovation and Science, has described UOW’s efforts in engineering and materials science and innovation as a model for the nation.

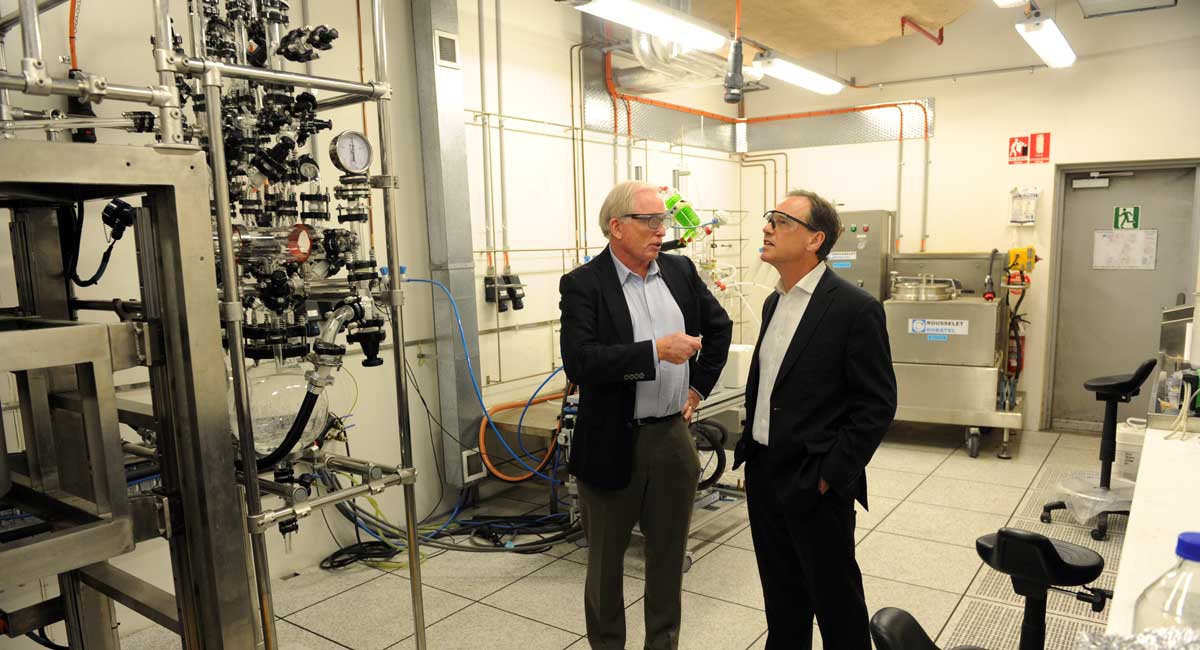

The comments were made during a visit to ¾«¶«´«Ã½, which included a visit to UOW’s major science and technology research centres.

Mr Hunt toured UOW’s (WERG), in the (EIS), and was shown firsthand how key skills and knowledge in robotics and automation was supporting manufacturing industries.

The researchers and technical staff continue to play a key role in Australia’s defence capabilities, including the development of welding techniques in partnership with Thales for the armoured troop carrier.

They are currently developing manufacturing methods for the , a next-generation, highly mobile protected vehicle.

UOW is also contributing to developing skills in manufacturing to support Australian workers through a welding training centre that ‘trains the trainers’.

EIS Dean Professor Chris Cook said it would help develop welding and manufacturing methods to the required world quality standards.

It would also allow welders to up-skill and attain internationally recognised certification to work on major projects.

“For just one example, to build the new submarine fleet, Australia will need about 1000 highly skilled welders,” Professor Cook said.

“The partnership with the Welding Technology Institute of Australia and TAFE will enable us to create a one-stop-shop for welding R&D and training.”

Mr Hunt said it was a great example of where science meets innovation.

“To make submarines in Australia you need the best welders in the world… the people who teach the welders are here in ¾«¶«´«Ã½.” he said.

“What we’re seeing at the ¾«¶«´«Ã½ of ¾«¶«´«Ã½ is some of the best advanced manufacturing training and teaching.

“It means more welding jobs for Australians, not just here in the Illawarra but in Adelaide and elsewhere in the country.”

Mr Hunt also toured the Innovation Campus, getting insights into the advances in materials for energy and health, along with the 3D-printing technology being used to rapidly prototype and test new ideas.

Rounding out the visit, Mr Hunt met the entrepreneurs behind the start-ups at the recently opened iAccelerate Centre who are driving economic renewal and diversity in the region.

“We know that growth in university precincts with commercial firms attached to university’s have on average two-and-a-half times the national growth rate,” Mr Hunt said.

“We want to take that model here in ¾«¶«´«Ã½ and build that with other universities around the country.

“This is a steel town but it’s becoming and advanced manufacturing town and the bridge to that is the university. It’s a go-ahead university and a go-ahead town.

"The science that’s being done here is real and applied it matters to people."

Earlier in the day, Mr Hunt toured Bluscope’s Port Kembla plant, describing its recent financial results as a “great story of a turnaround” and “innovation in action”.

He , “the only way in a competitive world our businesses can thrive and be successful is if they innovate and they’re world-class competitive in their own right”.